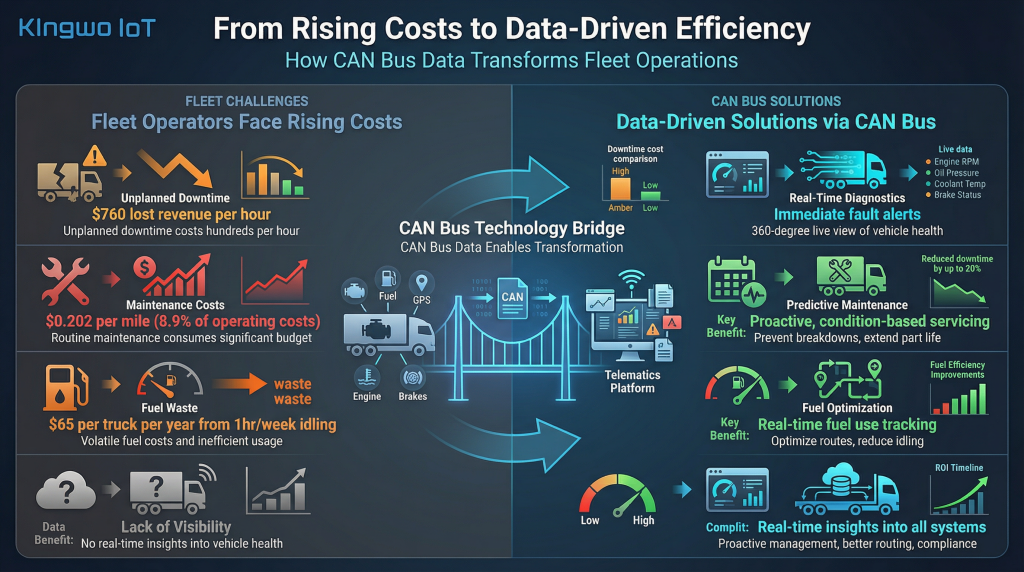

Fleet operators today face rising costs and tight margins. Unplanned downtime can cost hundreds of dollars per hour – on average around $760 lost in revenue for each hour a truck is idle. Routine maintenance consumes a significant portion of operating budgets (truck maintenance averages about $0.202 per mile, or roughly 8.9% of total operating costs). At the same time, fuel costs remain volatile – even idling a vehicle just one hour per week can waste an extra $65 per truck per year. To tackle these challenges, modern fleets are turning to data-driven solutions. A key enabler is the Controller Area Network (CAN) bus, the vehicle’s internal data network that connects sensors and control units. By tapping into CAN bus data through fleet telematics, managers gain real-time insights into engine health, fuel use, driver behavior, and more – allowing proactive maintenance, better routing, and compliance reporting.

In this article, we explain what CAN bus is and how it works, why it matters for fleets, and how capturing CAN data can reduce maintenance costs, optimize fuel efficiency, and simplify compliance. We draw on recent industry research and examples to highlight current pain points and quantify the benefits of CAN-based telematics. (Kingwo’s IoT expertise makes it easier for fleets to harness these insights, as we discuss at the end.)

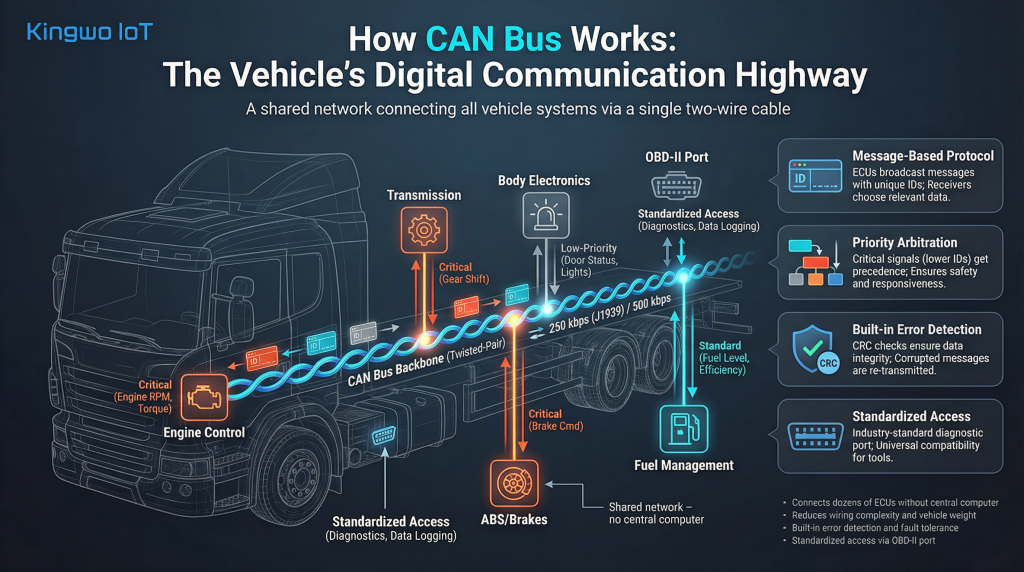

The Controller Area Network (CAN) bus is a vehicle’s digital communication highway. It is a standardized, message-based protocol that lets electronic control units (ECUs) – like the engine control module, transmission controller, ABS system, etc. – exchange data without a central computer. Think of it as a common “data bus” where every ECU can broadcast status messages and receive others’ messages, rather than having individual wired links to each other. Each CAN message carries a unique identifier (priority) and data payload, so critical signals (e.g. brake commands) get precedence over less urgent data.

Modern vehicles often have dozens of ECUs sharing the same two-wire CAN cable. This shared network greatly reduces complexity and weight: instead of massive point-to-point wiring, a single twisted-pair cable connects all nodes. That simplicity cuts vehicle weight and helps improve fuel efficiency. Importantly, CAN includes built-in error detection (Cyclic Redundancy Checks) and fault-tolerance: a faulty ECU or wire simply stops sending data without bringing down the whole network.

CAN has been the standard in automotive electronics for decades. It was introduced by Bosch in the mid-1980s and became commonplace by the 1990s. Today nearly all vehicles (especially heavy trucks) use CAN for diagnostics and control. In fact, since 2008 U.S. regulations have required heavy-duty vehicles to use standardized OBD-II ports (which rely on the CAN protocol) for emission diagnostics. In other words, any truck made after 2008 will have a CAN bus you can access via the on-board diagnostic port.

CAN itself has a few variants. Classical CAN (ISO 11898-1) operates at up to 1 Mbps and uses 8-byte frames. More recently, CAN FD (Flexible Data-rate) was introduced; it lets messages carry up to 64 bytes of data and use higher bit rates (up to 8 Mbps). These enhancements accommodate the higher bandwidth needed in modern vehicles. The key point for fleet management is that all of this data – from engine RPM and coolant temperature to brake pressure and fuel level – is flowing on the CAN bus and can be captured by a telematics device.

On a high level, a CAN bus connects ECUs (nodes) via a two-wire differential pair labeled CAN_High and CAN_Low. Each node has a CAN controller and transceiver: the controller formats outgoing messages and processes incoming ones, while the transceiver converts digital signals to bus voltages (and vice versa). When the network is idle, both wires sit at ~2.5 V (recessive state). To send a message, a node drives CAN_High toward 3.5 V and CAN_Low toward 1.5 V (dominant state), creating a 2 V differential. All other nodes see this as a valid message frame.

Messages on the bus follow a priority arbitration scheme. Each frame begins with an identifier field (11-bit or 29-bit, depending on CAN version) that indicates the content. If two ECUs start sending at the same time, the one with the lower ID value wins the arbitration and continues, while the other backs off and retries. This ensures critical messages (like engine control signals) are delivered with minimal delay. After the ID, each frame carries control bits, the data payload, and CRC/error-check bits. If any node detects a transmission error (via CRC mismatch or other error), it automatically issues an error-frame, causing the sender to retry.

In practice, common CAN speeds in trucks are around 250 kbps (J1939 protocol on heavy trucks) or 500 kbps. Low-speed/Fault-tolerant CAN (125 kbps) is often used for body electronics (doors, lights, etc). CAN FD networks can start at 1 Mbps arbitration then switch to 2–8 Mbps for the data phase. These options let vehicle designers balance speed, cost, and robustness.

Importantly, standard diagnostic tools (scan tools) can tap into the CAN bus via the OBD-II port on every modern vehicle. Because the bus uses industry-standard message formats (e.g. SAE J1939, J1708, ISO-15765), one scan tool can read trouble codes and live data from any compliant truck. This standardization is a huge benefit: a single telematics device can capture data from a mixed fleet of trucks, eliminating the need for vehicle-specific wiring.

Leveraging CAN bus data transforms fleet operations. By capturing the raw data from a vehicle’s CAN bus, fleets gain real-time visibility into every aspect of vehicle health and performance. This leads to several concrete benefits:

These benefits combine to lower total cost of ownership for vehicles. The simplified wiring and fault-tolerant design of CAN also contribute: a CAN network weighs less than complex point-to-point wiring, boosting efficiency. The inherent reliability of CAN (messages get through even if one ECU fails) means fewer system failures. Collectively, these advantages translate into fewer breakdowns, smoother maintenance, and significant cost savings.

One of the most immediate uses of CAN data is real-time diagnostics. Every minute, a truck’s CAN bus is broadcasting the latest readings from dozens of sensors. For instance, engine control, transmission, ABS brake modules, and even aftertreatment systems send hundreds of distinct messages per second. A modern telematics unit plugged into the OBD-II port or directly wired into the CAN network can capture this stream of data.

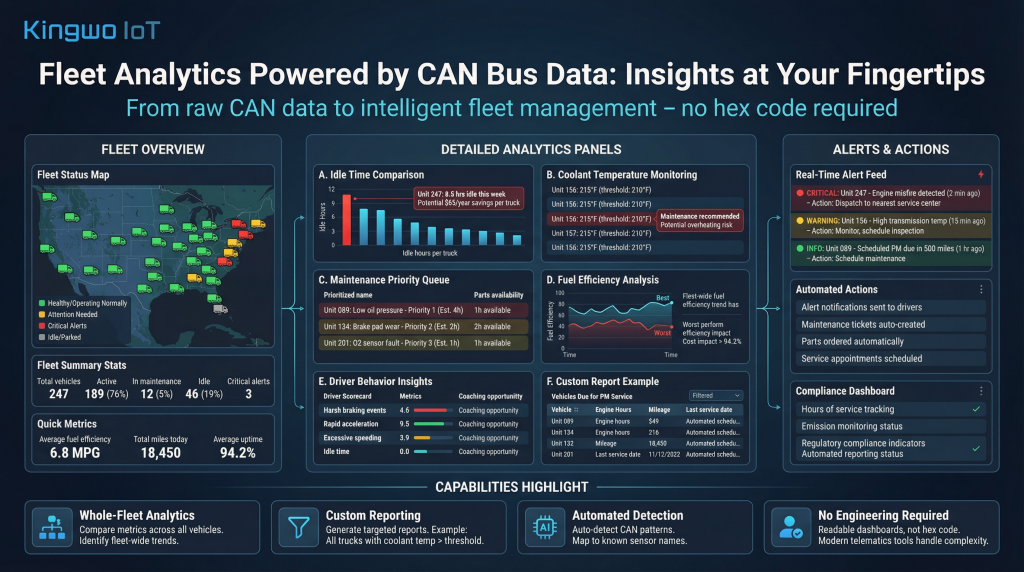

Once captured, the raw CAN frames (in hexadecimal) are decoded into meaningful metrics. For example, one CAN ID might represent engine coolant temperature; when decoded, it reads “195°F”. Using industry-standard DBC files and parameter definitions (e.g. J1939 Parameter Groups), fleets translate every frame into human-readable data like vehicle speed, RPM, oil pressure, turbo boost, and more.

The practical result is a live dashboard of vehicle health. Fleet managers can watch engine temperature, oil levels, battery voltage, etc., in real time. If a check-engine light comes on, the system immediately logs the exact Diagnostic Trouble Code (DTC) from the CAN data and notifies maintenance. Mechanics no longer have to guess or rely on driver reports. They see exactly which subsystem threw a fault and what the operating conditions were at that time (thanks to freeze-frame data). This remote diagnostics capability means many issues can be diagnosed (and sometimes fixed) without bringing the truck into the shop. For example, if a sensor is flaky, a remote driver can be alerted, and the mechanic can order the right part before the truck even arrives.

Overall, real-time CAN telemetry turns every fleet vehicle into its own sensor network. Instead of sporadic manual inspections, a fleet has continuous visibility. This not only catches problems early but also allows performance monitoring. Managers can see if engines are running hotter than normal, or if brake usage is unusually high (indicating driver habits to be corrected). This “living data log” of vehicle diagnostics is now a cornerstone of modern fleet telematics.

Traditional maintenance schedules (e.g. service every 10,000 miles) treat all vehicles the same. With CAN bus data, fleets can adopt predictive maintenance: servicing each vehicle at the optimal time based on actual condition. Hundreds of CAN parameters – engine oil pressure, differential temperatures, battery charge cycles, DEF (diesel exhaust fluid) levels, etc. – can signal wear or failure in advance.

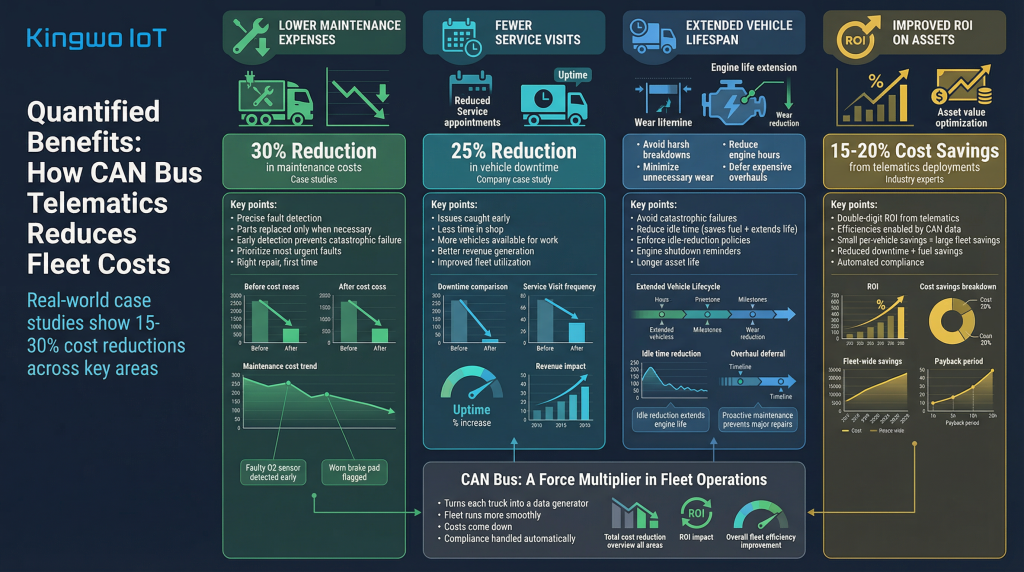

For example, if the CAN bus reports a slow decline in transmission fluid pressure over weeks, analytics software can flag a potential seal leak. If the particulate filter backpressure gradually rises, the system schedules a regen or service before the engine derates. Because CAN bus networks use redundant architectures on trucks, critical systems keep running during such analysis, ensuring the vehicle stays operational. In practice, large fleets have reported significant reductions in breakdowns: one case study showed a fleet achieved a 30% reduction in maintenance costs and a 25% drop in vehicle downtime by using CAN-driven predictive analytics.

Furthermore, CAN-based alerts often precede driver-reported symptoms by days or weeks. Fleets receive automatic warnings when monitored metrics deviate from their normal range. Maintenance can then be scheduled during planned downtime rather than emergency repairs. This shift from reactive to proactive maintenance not only saves parts and labor but also maximizes uptime. In fact, predictive programs using CAN data can extend mean time between failures (MTBF) dramatically – one client saw MTBF grow by 28% with guided fault analytics.

In summary, CAN bus telemetry keeps trucks on the road and parts on schedule. It turns unexpected failures (and the associated costs of towing, lost revenue, and driver downtime) into predictable maintenance events. Given that even a single breakdown can cost a fleet thousands in rush repairs and lost business, predictive maintenance is a game-changer for cost control and service reliability.

Fuel is often the single largest operating expense for fleet companies. CAN bus data offers powerful levers for fuel reduction. Since modern engines track fuel flow and consumption in real time, telematics systems can report exact fuel use per mile or per hour of operation. Managers use this to establish benchmarks and spot inefficiencies.

For instance, if one truck’s fuel efficiency suddenly drops, the CAN feed might reveal it’s due to clogged filters, tire issues, or driver behavior. By correlating fuel data with other CAN metrics (engine load, RPM, throttle position), fleets can detect waste. Studies show that effective telematics use – which inherently includes CAN fuel data – cut fuel costs by up to 14%. Simple actions like reducing idle time (idling can burn a gallon per hour), training drivers to shift gears properly, or minimizing A/C load can add up.

Another example: tire pressure monitoring via CAN (or CAN-integrated TPMS) can prevent underinflation. Properly inflated tires roll more easily, reducing fuel burn. IoT For All notes that catching something like low tire pressure proactively can “improve fuel efficiency” and reduce risks of blowouts. Similarly, CAN-based speed control (ensuring trucks do not exceed optimal cruising speeds) yields fuel benefits.

Research supports these savings. The U.S. Department of Energy notes that driver behaviors like speeding or harsh braking can lower highway fuel economy by 15–30%. Programs that feed this information back to drivers (via dashboards or incentives) can improve average gas mileage by about 3–10%. Telematics platforms use CAN data exactly for this purpose: they generate fuel efficiency reports and coach drivers. For example, if CAN data shows frequent 90+ mph driving or unnecessary idling, the system alerts the driver and fleet managers to correct it.

Beyond fuel, fuel-related cost savings include longevity of parts. Less aggressive driving means brakes and engines last longer. According to kingwo’s fleet cost guide, each hour of weekly idling wastes around one gallon of fuel, which means thousands of wasted dollars fleet-wide each year. By reducing idling through CAN-based monitoring and alerts, a fleet can recoup a significant portion of that waste. All these measures combined typically generate double-digit percentage improvements in fuel economy across a fleet.

Safety and regulatory compliance are critical concerns for fleet operators. CAN bus data plays an important role in meeting these requirements. In the United States, for example, the ELD (Electronic Logging Device) mandate requires that driver hours are digitally logged and tied to the vehicle’s engine. By using a telematics device connected to the CAN bus, fleets automatically capture engine on/off and mileage data without manual intervention. This ensures accurate hours-of-service records and avoids costly fines for non-compliance.

Similarly, some regions mandate automatic emissions reporting. Nevada’s Continuous Monitoring Program requires heavy vehicles (2008+ model year) to continuously report emissions data via a connected system. Since emission control systems (like diesel particulate filters and EGR) report status via the CAN bus, telematics systems can provide the required data stream. This automation eliminates manual inspections and paperwork, saving time and reducing errors.

Tax compliance is another area where CAN data helps. Under the International Fuel Tax Agreement (IFTA) and International Registration Plan (IRP), fleets must allocate fuel use and registration costs based on miles driven in each jurisdiction. With CAN-sourced odometer and fuel flow data, fleet software can automatically generate IFTA reports. This level of data detail simplifies audits and ensures carriers pay exactly what they owe in fuel taxes (no more or less).

From a safety standpoint, CAN bus can also log critical events for audits. Harsh braking, seat belt use, and airbag deployment are all signaled on the vehicle network. If a violation occurs, a telematics system can timestamp it and send an alert. Over time, this creates a data trail showing that vehicles are being operated safely and legally. In summary, integrating CAN data into fleet systems turns compliance from a headache into a byproduct of normal operations. Instead of drivers filling forms, the CAN-enabled telematics does the logging in the background, ensuring fleets stay on the right side of regulations.

To extract this wealth of information, fleets need the right hardware and software. A typical CAN-enabled telematics setup involves a device (the telematics unit) that plugs into the vehicle’s OBD-II port or directly into the CAN bus wiring harness. Once powered, the device listens to CAN messages (often at the SAE J1939 protocol on heavy trucks, 250 kbps) and records all traffic.

Data capture and decoding: The telematics unit captures raw CAN frames and sends them to a cloud platform. There, a CAN decoder interprets the IDs and data. For J1939 and similar standards, each message ID corresponds to known parameters. The decoder maps each data field (usually hex values) to real-world units (e.g. kPa, °C, %). For proprietary or newer vehicle models, fleets can use manufacturer-specific DBC (data exchange) files provided by OEMs to understand the messages.

Steps to access CAN data: In practice, deploying CAN logging involves:

With data flowing into the fleet management software, the possibilities multiply. Managers can run analytics on whole fleets – for example, comparing idle times by vehicle, or detecting outlier behavior. They can generate custom reports for maintenance tasks (e.g. show all trucks with coolant temp above a threshold). Importantly, this process does not require special engineering skills if using modern telematics tools. These tools often auto-detect CAN patterns and map them to known sensor names, presenting fleet managers with readable dashboards rather than hex code dumps.

All the above leads to one ultimate goal: reducing overall fleet costs. By using CAN bus telematics, fleets cut both direct and indirect expenses.

In short, CAN bus is a force multiplier in fleet operations. It turns each truck into a data generator. When that data is harnessed, the fleet runs more smoothly, costs come down, and compliance is handled automatically.

The Controller Area Network may have been designed for vehicles, but in today’s fleets it serves a broader purpose: data integration and insight. By tapping into the CAN bus, fleet managers unlock real-time diagnostics, predictive maintenance, fuel optimization and compliance reporting – all of which address key pain points like downtime, cost overruns, and regulatory burdens. Recent studies show that fleets using telematics and CAN data cut fuel use by double-digit percentages and slash maintenance expenses by up to 30%.

Implementing CAN data logging does require expertise – from identifying the right signals to decoding them – but the payoff is clear. This is where Kingwo’s IoT and vehicle-data integration expertise comes in. With our experience in telematics solutions, we help fleets connect to their vehicle CAN buses and translate raw data into actionable intelligence. By partnering with Kingwo, fleet operators can confidently deploy CAN-based telematics, knowing they will gain strategic insights without getting bogged down in the technical details.

In the connected fleet of today, CAN bus is more than just a wiring standard – it’s the source of intelligence that drives smarter maintenance, safer operations, and lower costs. Fleets that leverage this data will stay ahead of the competition and keep their vehicles moving efficiently.

English

French

Portuguese

Spanish