Fleet operators today manage increasingly complex operations across wider geographies and tighter delivery windows. Yet many organizations still lack timely, reliable visibility into vehicle location, status, and exceptions. This visibility gap directly translates into inefficient routing, delayed responses, missed delivery windows, and avoidable service failures.

At the same time, structural cost pressures continue to intensify. Fuel price volatility, rising maintenance expenses, and stricter regulatory requirements are compressing margins across the logistics and transportation sector. When asset tracking and fleet monitoring rely on manual processes or spreadsheet-based reporting, errors accumulate and real-time decision-making becomes impossible.

Without accurate, continuous operational insight, fleet-based logistics companies struggle to control costs, improve utilization, and maintain service quality at scale. Against this backdrop, telematics is increasingly viewed not as an optional add-on, but as a foundational capability for modern fleet operations.

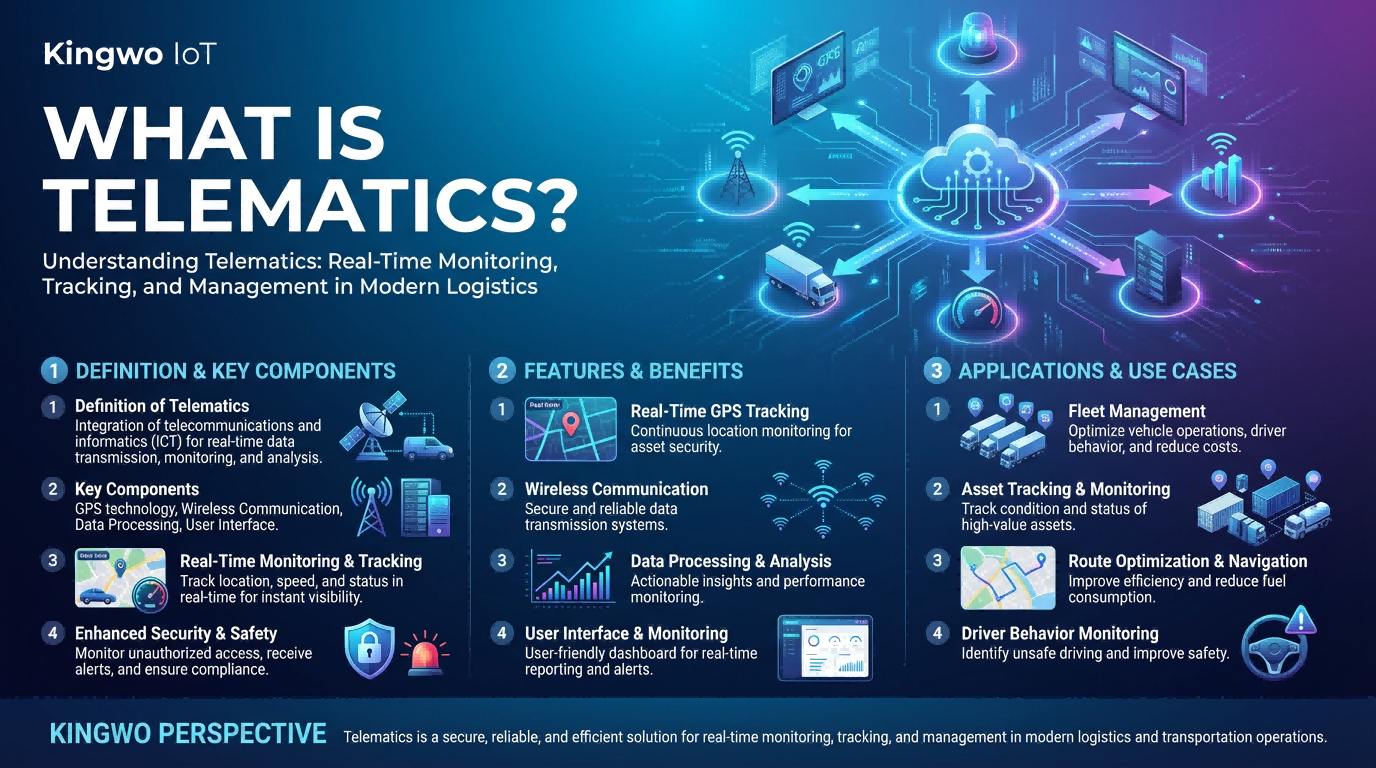

Telematics is a technology paradigm that combines telecommunications and informatics to monitor and manage vehicles, drivers, and mobile assets. In logistics and fleet management, telematics refers to systems that collect data from vehicles through onboard devices. These devices typically use GPS to track location and integrate with engine diagnostics to capture vehicle health and performance data. Telematics systems can also include sensors for fuel level, cargo temperature (for refrigerated transport), or other specialized data. Overall, telematics turns raw vehicle data into actionable insights for fleet operators.

Telematics systems involve three key components: hardware, connectivity, and software. Each vehicle is equipped with a telematics control unit (TCU) or device. This onboard hardware includes a GPS receiver, a cellular modem, and various sensors. The TCU connects to the vehicle’s computer (via the OBD-II port or CAN bus) to read engine data such as speed, RPM, and fault codes. It can also interface with accelerometers, cameras, or cargo sensors. As the vehicle moves, the device continuously collects location and performance data.

Next, the telematics device transmits collected data over a wireless network. Most systems use 4G/5G cellular networks (or occasionally satellite in remote areas) to send information to a central server. Some advanced devices may also use Wi-Fi or Bluetooth for data offload when the vehicle returns to a depot. This connectivity ensures near real-time data flow, giving dispatchers and managers up-to-date tracking information on the fleet.

Finally, on the software side, the data reaches a cloud-based telematics platform or fleet management system. The platform processes raw data, applies analytics, and presents insights through web dashboards or mobile apps. Fleet managers can log in to view live maps of vehicle locations, generate reports on fuel usage, idle time, or driver behavior, and set up alerts – for example, if a truck deviates from its planned route or exceeds a speed threshold. The software often integrates with other enterprise systems, such as maintenance management or CRM, to provide a unified operational view.

Implementing a telematics system can transform fleet operations across multiple dimensions. Key benefits include:

Overall, these benefits lead to higher productivity, reduced operating costs, and enhanced service quality. Many fleet operators see a return on investment within months of deploying telematics, as savings from fuel efficiency and maintenance quickly add up.

A typical telematics system architecture combines in-vehicle devices, communication networks, and back-end platforms:

This layered architecture ensures data flows seamlessly from the vehicle to decision-makers, enabling smarter fleet management.

Telematics has become a critical technology for modern logistics and fleet operations. By bridging the gap between vehicles on the road and managers in the office, a telematics system delivers transparency and control. It addresses core industry problems like rising costs, regulatory complexity, and the need for faster decision-making.

Integrated telematics and tracking solutions, such as those offered by Kingwo, package these capabilities into a cohesive platform. Kingwo provides GPS fleet tracking devices, sensor integration, and cloud software that work together. This means a logistics operator can get end-to-end visibility—knowing where every asset is, how it’s performing, and how to improve operations.

In an era of increasing competition and customer expectations, adopting telematics is no longer optional. It is an investment in efficiency, safety, and growth. Companies that leverage telematics systems effectively are better positioned to reduce costs, comply with regulations, and provide superior service.

English

French

Portuguese

Spanish